Advertise Follow Us

Nutrient Management

ARTICLES

Which Planter is best for closing seed slots in clay soils?

Managing Inputs for Maximum Returns

No-Till Discussion: Single Species Cover Crop vs. Mix

PRODUCTS

Getting More From Your Nitrogen Investment

Discover numerous tools and application strategies at your disposal today including the case for moving nitrogen (N) applications in corn to later in the season and the potential that crop sensors are showing for targeted N applications to increase efficiency and profitability. Plus, learn about certain species of cover crops that can fix significant amounts of N.

View8th Annual Responsible Nutrient Management Practitioners Program - NNTC 2016 Presentation - MP3 Download

Agro-Culture Liquid Fertilizers and No-Till Farmer recognize three no-tillers judged to be environmentally, economically and practically responsible with their no-till nutrient management programs. The fertility practices and techniques utilized by these no-tillers — recognized as Responsible Nutrient Management Practitioners — will provide you with valuable ideas to consider in your own no-till operation.

ViewTightening Your Nitrogen Budget by Getting it Right - Joe Nester - NNTC 2016 Presentation - MP3 Download

Nitrogen rates have been hard to pin down and many times are completely wrong. A good way to describe the need for nitrogen is “variable.” Joe Nester, an independent crop consultant, discusses the nitrogen plot work his company, Nester Ag, has done over the last 10 years and provide some tips for nitrogen management on your no-till farm. Nester also talks about new soil tests he is using to develop variable-rate nitrogen recommendations, and he presents some tools that can help you tighten your nitrogen budget.

ViewTaking No-Till Further with Water Management, Positive Nutrient Practices - Mike Werling - NNTC 2016 Presentation - MP3 Download

Mike Werling has been conservation farming for more than 30 years. In this time, the Decatur, Ind., farmer has adopted never-till, cover crops, waterways, water sediment and control basins, a two-stage ditch and drainage water management structures to further advance his conservation efforts. Werling shares his conservation journey and the practices that have markedly improved his soil tilth. In this presentation, he also provides information on studies and test plots he’s been involved with and share examples of practical application. Werling, who operates in the Maumee Watershed, explains his nutrient management practices and the positive effects they may have on Lake Erie’s water quality.

ViewManaging Micronutrients with Soil Testing and Fertilizer - Ray Ward - NNTC 2016 Presentation - MP3 Download

For many years, we’ve considered fertilizer to be nitrogen, phosphate and potash. But as yields have increased, we’ve continued to remove secondary nutrients and micronutrients at greater amounts. Higher yields also increase the daily demand for these nutrients, creating potential micronutrient deficiencies. How can we tell if our crop is deficient in micronutrients? Ward Laboratories founder and president Ray Ward discusses the two methods of evaluation: soil testing and plant analysis, and what the proper sampling protocol is for each. He also explains how to correct micronutrient deficiencies, including the timing of soil and foliar nutrient application for each micronutrient.

ViewSoil Testing to Achieve Adequate No-Till Nutrient Levels - Ray Ward - NNTC 2016 Presentation - MP3 Download

Every time we remove crops from the field, we remove all of the plant nutrients. If the soil is short on available nutrients, either commercial or organic fertilizer must be applied to the field to maintain productive yields. But if the soil has a high supply of nutrients, soil testing is a must to avoid over-application, which may contribute to environmental problems. Ray Ward will discuss the essential nutrients plants need and the optimal soil test value of each nutrient. The founder and president of Ward Laboratories in Kearney, Neb., will also talk about the importance of returning animal manures to the fields at proper rates.

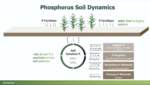

ViewWhy Phosphorus is Leaving the Farm and What to Do About it - Joe Nester - NNTC 2016 Presentation - MP3 Download

Phosphorus has come under fire lately, especially around Lake Erie where toxic, blue-green algae blooms caused by phosphorus runoff have plagued the lake’s western basin the last several years. Why is this happening? Nester Ag owner and independent crop consultant Joe Nester from Bryan in northwest Ohio shares his thoughts on why phosphorus management is different today than it used to be. He talks about what practices no-tillers can employ on their farms to ensure their crops have adequate phosphorus while minimizing loss.

ViewHow Can I Place My ‘N’ and ‘P’ Better in a No-Till System? - John Fulton - NNTC 2016 Presentation - MP3 Download

With environmental policies influencing the timing and placement of fertilizers, it’s important to improve the application toolbox without sacrificing farm profitability. Placing nitrogen and phosphorus below the soil surface has been a suggested way to reduce off-site transport of nutrients, but at times, field capacity (ac/hr) may be sacrificed. Moving forward, the ability to both accurately place nutrients and apply them at the right time will be important for the no-till operation. In this presentation, John Fulton discusses opportunities for timing and placement of nitrogen and phosphorus, and how new technology can help enhance delivery. The Ohio State ag engineer also discusses environmental risks, agronomic response and application field capacity, as well as tips to consider for success.

ViewEverything You Need to Know About Micronutrients

The Potassium Paradox — A Path To Profitability With No-Till - Saeed Khan - NNTC 2015 Presentation - MP3 Download

No-tillers should be concerned with soil test values assigned to potassium and the resulting intensive use of muriate of potash (KCI). Saeed Khan says recent studies show soil test values to be of no interpretative value due to drastic fluctuations and fail to differentiate potassium buildup from depletion. Levels have been found to increase even in the absence of applied potassium.

View